2.1 Intelligent robotic systems

Participants: J. Pomar, V. López

The global livestock production sector is facing major challenges to which it has to respond in both the short and medium-term. One of these challenges is the increase in global demand for meat and animal products, which is expected to rise by at least 40% in the next 15 years. The first question facing the sector is how to achieve high quality, sustainable, and food safe meat products that can meet this demand. At the same time, the environmental impact of the livestock sector is an important issue with effects on climate change and the preservation of the environment.

Both problems lead to the need to improve the efficiency of production systems, in particular the feed efficiency of animals, especially monogastric animals. There is also a growing concern and interest in animal health concerning food safety and human health at the same time as there is a need to improve animal welfare.

All these problems and needs can be addressed through precision livestock farming (PLF). PLF has been defined as the intelligent management and care of animals on an individualised basis through continuous automated monitoring/control of animal production/reproduction, health and welfare, allowing for rapid corrections or interventions when deviations from normal are observed. Generally speaking, PLF is based on the intensive use of advances in ICT and animal science and aims to help farmers improve the efficiency, quality, welfare and health of livestock production in a sustainable way.

Intelligent robotic systems

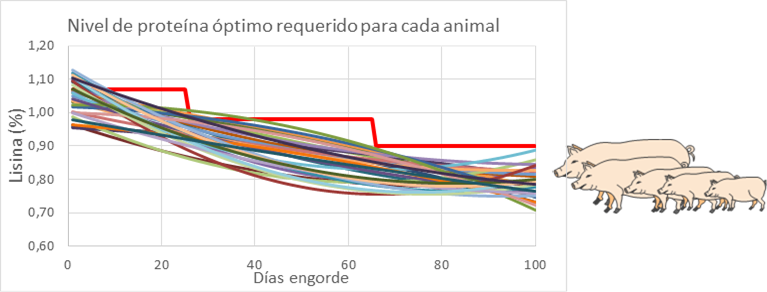

Precision feeding (PF) is one of the great achievements in this field today. In short, we can define it as a new technology for livestock feeding that makes it possible to provide each animal on the farm with feed in the right quantity and with a composition adjusted to its needs, at that moment in time. This is shown in the following graph in which we can highlight two key aspects: 1) each animal has different needs and 2) the needs of each animal (especially in protein) vary significantly over time.

What do we need to implement Precision Feeding on a farm? (1) To be able to determine the needs of each animal in real-time (daily), and, (2) To have an intelligent machine capable of feeding each animal with a feed adjusted to its needs.

Precision feeding robotic equipment

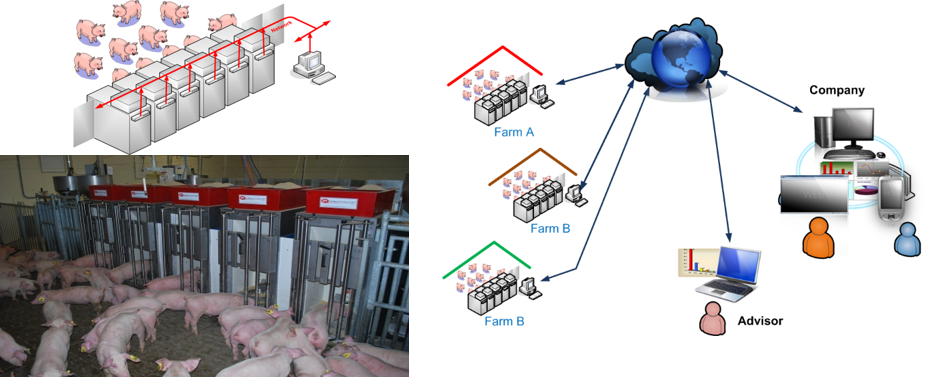

With this challenge in mind, in 2004 the research group started a line of R&D to promote "precision pig farming", initiating the design and development of a robotic system for precision feeding and intelligent management. This project, which required a great deal of R+D, was planned jointly with the Swine Research and Development Centre of Agriculture and Agri-Food Canada, which specialises in the field of pig nutrition. As a result of this collaborative work, significant progress has been made. The development of these feeders is currently led by different collaboration agreements between the UdL and the company Exafan SAU, allowing the improvement of the functionalities of both the robotised equipment and the feeder management programme

This robotic equipment enables advanced real-time farm management with telematic access and technical, veterinary and business decision support tools. Among the results obtained with this precision feeding technology, the IPF-UdL feeders are demonstrating that it is possible to simultaneously reduce protein consumption, reduce nitrogen in slurry (10-30%), enhance animal growth and improve processing rate. With this robot, it becomes feasible to measure and monitor growth and feed consumption automatically in real-time, which are essential to implement precision feeding and enhance the automation of monitoring tasks.

Data analysis & Decision making based on multi-agent architecture

This second sub-line is complementary to the previous sub-line, as it aims to develop methodologies and tools for analysis of the information collected by the precision feeder. The maturity of the market for both white and Iberian pork pushes the sector to compete strongly on price and quality, which forces companies to develop new tools and strategies that allow them to improve their production process to maintain their competitiveness.

Some of these new tools are based on theoretical models to calculate the nutritional needs of the animals. By determining the individual needs of each animal it is possible to optimise the inputs used. These models must be correctly calibrated against a reference population to ensure that the estimation is accurate. However, these models are challenged by the difficulty of calibration, as animals in real populations may follow different growth patterns than those observed in reference populations.

Modeling and simulation of complex Systems

Developing a model aims to obtain responses from it that would take time and be costly to obtain in a real system. The execution of this simulation consists of carrying out experiments on the model rather than on the real system. It must be ensured that the model is a "valid" representation of reality. In addition, the reliability with which the results are presented must be calculated.

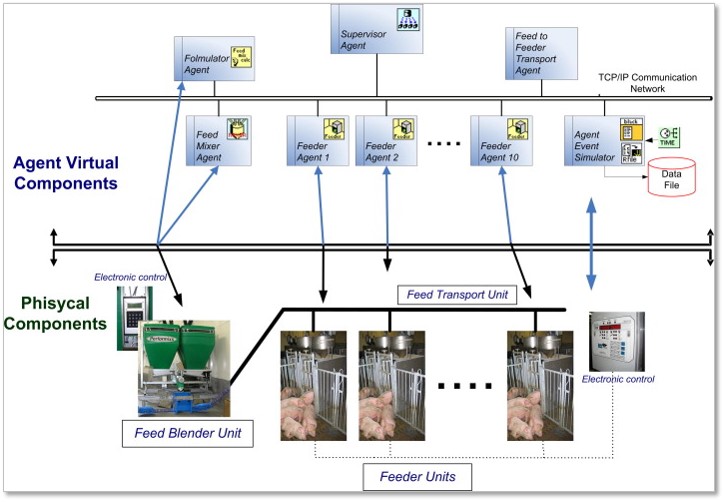

The work carried out in this sub-line has consisted of developing several virtual modules, following a multi-agent architecture, which represent real components of a farm and perform specific functionalities. One of the aims is to develop a simple communication language - called ACL (Agent Communication Language) - with which the agents involved interact with each other according to specific purposes.