1.5 Precision Crop Protection

Participants: J. Llorens, A. Escolà, J. Arnó, C. Román, E. Gregorio, J.R. Rosell-Polo, F. Solanelles, F. Camp.

Precision Crop Protection can be defined as management that, using technological advances, optimizes the use of plant protection products (PPP) or pesticides maximizing yield, production quality and minimizing their impact and environmental risk. The optimization of the use of PPP in Precision Agriculture will be defined by the application of the minimum effective dose (kg/ha) adapted to the characteristics of the target that needs to be treated within each plot. Advances in machinery, software, positioning systems (GNSS, Global Navigation Satellite Systems), vegetation characterization sensors (near and remote) and variable-rate application technologies offer the possibility of adjusting the application to the practice. In this sense, the GRAP started its work in the field spray application techniques more than 20 years ago, long before the official creation of the research group in 2002. One of the first research lines was the variable-rate application of PPP while developing a prototype of orchards sprayer capable of modifying the sprayed flow rate proportionally to the size of the target canopy for and adjusted and more efficient treatment (Escolà et al., 2013; Solanelles et al., 2002). All the work in this line of precision PPP application aims to achieve a uniform product deposition on the surface of the leaves, regardless of the size of the canopy. And, at the same time, reduce the amount of product deposited on the ground or that which is lost due to the effect of drift, optimizing in this way the applications of PPP and ensuring the protection of the environment.

Analysis of quality and efficiency of treatments

In the process of improving PPP applications, it is important to have tools for the analysis of the quality and efficiency of the treatments. These tools allow the assessment of the amount of product that is retained in the treatment target(crop, leaves, fruits, trunk, soil,...) and determine that amount that does not reach its goal and, hence, is lost by drift or by deposition in unwanted areas.

That is why the GRAP has experience in performing tests following standardized ISO protocols (International Organization for Standardization, https://www.iso.org) for the quantification of deposition and drift (Román et al., 2022 , 2021, 2020, 2019; Torrent et al., 2020, 2017). These protocols are contained in the following documents:

- ISO 5682-1:2017: Equipment for crop protection – Spraying equipment – Part 1: Test methods for sprayer nozzles.

- ISO 5682-2:2017 Equipment for crop protection - Spraying equipment - Part 2: Test methods for hydraulic sprayers.

- ISO 5682-3:2017 Equipment for crop protection - Spraying equipment - Part 3: Test methods for volume/hectare adjustment systems of agricultural hydraulic pressure sprayers.

- ISO 9898: 2000 Equipment for crop protection – Test methods for air-assisted sprayers for bush and tree crops.

- ISO 22522:2007 Crop protection equipment – Field measurement of spray distribution in tree and bush crops.

- ISO 22866:2005 Equipment for crop protection – Methods for field measurements of spray drift.

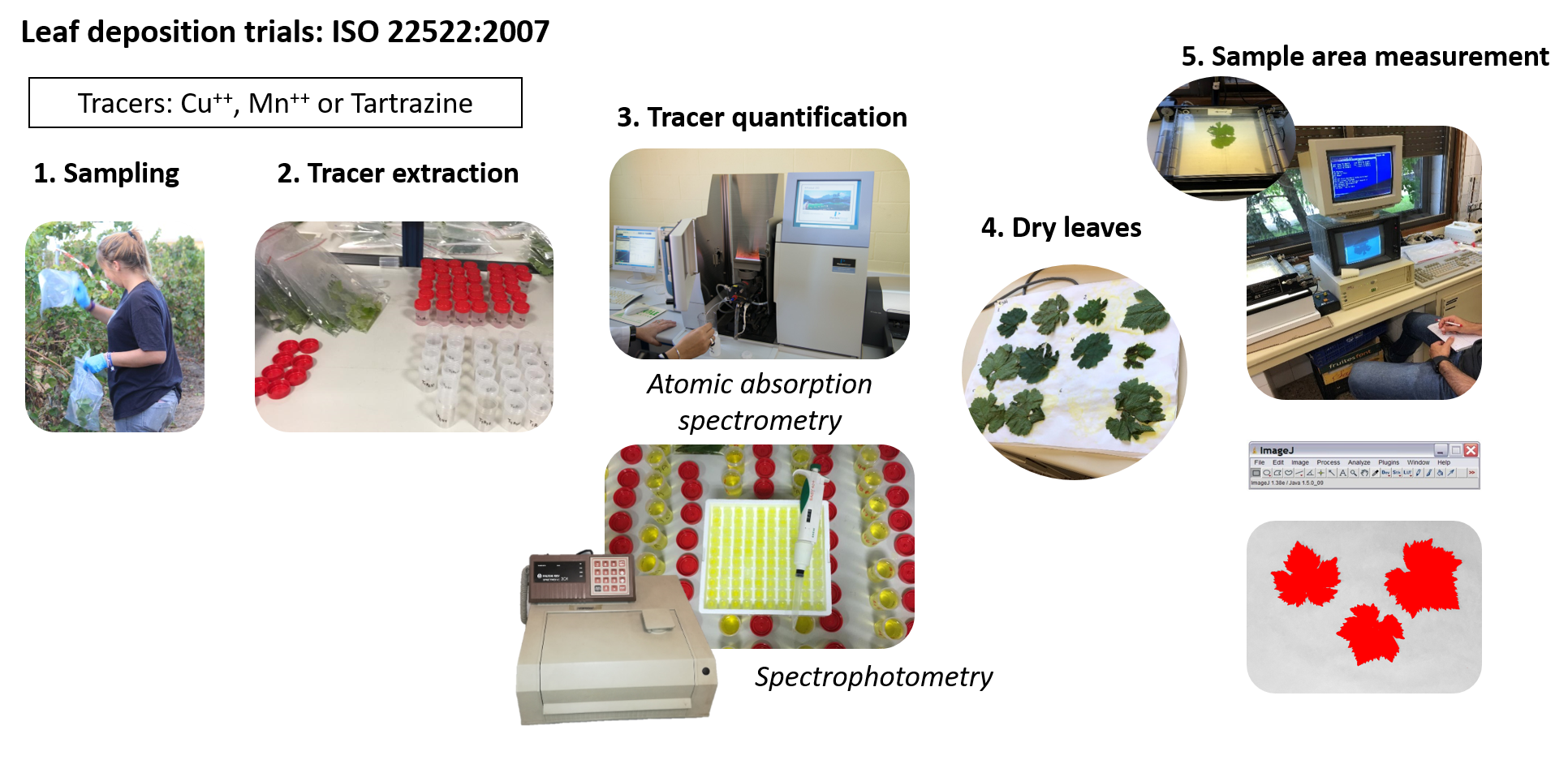

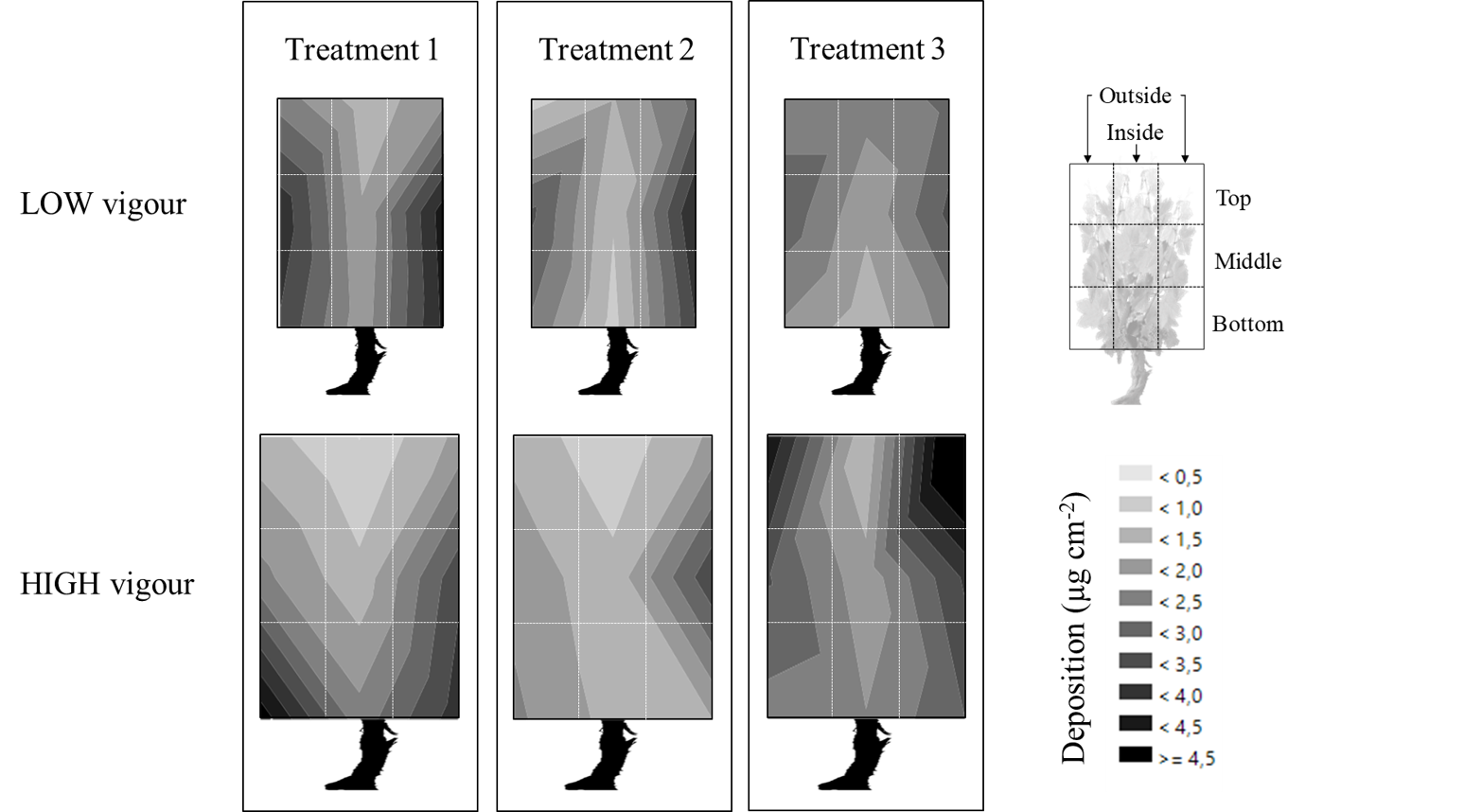

These quality and efficiency analysis of applications are made through the use of tracers (metal chelates, food dyes, fluorescent dyes, ...) that allow the assessment of the deposition on leaves, fruits, soil or surface of the object that is placed as a collector. Alternatively, a more qualitative analysis of the quality of the application can also be done using water sensitive papers, a method used in field demonstration days to check the effect of the adjustments made in the sprayers. In Figure 1, the procedure for extracting the tracer from the leaves in a deposition test is shown, and, in Figure 2, there is an example of the deposition results that allow analyzing how the product has reached a section of vegetation of vine from a plot with two levels of vegetative development.

Figura 1. Procedure used in a leaf deposition trial according to the ISO 22522:2007.

Figura 2. Example of the graphical deposition results in 2 types of canopies (Low vigour and High vigour).

Dose adjustment

In recent years, the GRAP has developed a web-based tool that facilitates the dose adjustment process in PPP applications in tree crops. The DOSA3D system computes the optimal application volume rate by estimating the leaf area index (LAI) and taking into account the overall efficiency of the application and the pest or disease to be controlled. The tool can be used for free on the following website: http://www.dosa3d.cat (Figure 3).

Figura 3. Caràtula de la pàgina web de DOSA3D.

This tool has been validated thanks to different field work that can be consulted in the following references of scientific articles (Planas et al., 2012; Román et al., 2022, 2021, 2020).

In the last update of the system, a tool has been introduced to facilitate the selection of the nozzles suitable for the treatment and the determination of the working pressure, either in uniform dose rate treatments or in treatments using a zone map in which the dose rate is adapted to intra-plot vigour variations.

Electronic control systems

The most common sprayers adjust the application volume rate by pushing the liquid that comes out of the nozzles at a certain pressure. The final application volume rate (L/ha) depends on the flow rate provided by the set of nozzles (in L/min), the sprayer forward speed (km/h) and the working width (m). In a conventional treatment, it is possible to provide a homogeneous application volume rate while maintaining a constant forward speed and working pressure. Or if that is the case, proportionally adjusting one of the parameters when the other parameter changes. To achieve a variable-rate spraying, it is necessary to install some type of technology that allows the application volume rate to be regulated according to the characteristics of the vegetation. Among the systems available for variable-rate applications we find those that act on the flow emitted by the nozzles. Table 1 shows the systems most used in tree crops.

Table 1. Technologies to adjust the nozzle flow rate.

|

Technology |

Description |

References |

|

On/Off system |

Control through electro valves to switch on and off the supply circuit for the nozzles |

(Wellington et al., 2012) |

|

Proportional or variable-rate electrovalves |

Variation of the nozzle flow rate by modifying the working pressure or the working frequency of the valves. |

(Campos et al., 2021; Escolà et al., 2013; Llorens et al., 2010) |

|

Pulse width modulation (PWM) electrovalves |

Variation of the duty cicle of continuously pulsing valves in order to vary the nozzle flow rate without modifying the working pressure and, hence, keeping the spray quality constant. |

(Llorens and Hewitt, 2019; Salcedo et al., 2020) |

In the entire process of adjusting the application through the electronic control systems, it is important to take into account the possibility of making the applications traceable. Today, many spray control systems allow this functionality. In this process, certain parameters of the application are georeference and recorded in order to control which volume rate is applied throughout. This information makes it possible to analyze the areas of the plot where the actual applied volume rate differs from the planned volume rate, either due to underdosing or overdosing. These two situations must be avoided due to the risk of generating problems, whether due to increased costs, phytotoxicity or unwanted environmental and personal exposure.

Variable rate pesticide application.

There are two approaches to variable-rate applications: real-time and map-based variable-rate.

In real-time variable-rate applications, the sensors that monitor the target (mainly vegetation), are mounted on the tractor or sprayer and as the equipment moves, the dose rate is adjusted on-the-go, on a continuous way.Several prototypes of real-time variable-rate sprayers have been developed (Abbas et al., 2020). Among the most prominent are, on the one hand, the orchard air-blast sprayer prototypes that characterize the vegetation in height sections using various ultrasound sensors and allowing different application volume rates to be applied to each height section (Escolà et al., 2013; Gil et al., 2007; Llorens et al., 2010). On the other hand, other prototypes integrate the scanning of the vegetation with LiDAR-based systems and variable-rate application with PWM (Pulse Width Modulation) valves (Chen et al., 2020; Salcedo et al., 2020).

Regarding map-based variable-rate applications, the characterization of the vegetation is done with the aim of defining management zones. For this purpose, LiDAR sensors (del-Moral-Martínez et al., 2020) or multispectral images (Campos et al., 2019; Román et al., 2022, 2021, 2020) can be used. Once the management zones have been created, a prescription map is generated by assigning a dose rate to each zone (Figure 4). The prescription map is loaded into the sprayer controller to adjust the sprayed volume rates on-the-go.

Figura 4. Example of a prescription map where BV means low volume rate, VM means middle volume rate and AV means high volume rate.

Real-time variable-rate applications allow more accurate and efficient applications to be done since the characterization of the vegetation and the adjustment of dose rates is on-the-go, achieving product savings between 30% and 80% (Wandkar et al., 2018). On the other hand, map-based applications use discrete (non-continuous) volume rates usually resulting in 2 or 3 different rates and, hence, the savings potential is expected to be lower. However, the electronics on board are simpler and allow to reduce costs and operational problems. And, more important in certain inputs, map-based applications allow the farmer to know the exact amount of input to load in the equipment beforehand, avoiding remnants, which is important when applying PPP.

LiDAR detection of pesticide spray drift

There are different techniques used to measure the drift produced in the application of PPP, such as the use of natural or artificial collectors, the use of active or passive collectors and the use of LiDAR technology (LIght Detection And Ranging). This research sub-line focuses on the latter.

A LiDAR system is a remote sensing instrument similar to a radar, with the difference that it emits light (laser) instead of radio waves. The operation principle of LiDAR consists in the emission of a laser beam pulse towards a target (in this case, the target is the spraying plume or drift cloud originated from the spray application) which partially backscatters this light (that is, part of the light emitted returns to the receiver). The photons arriving at the receiver are collected by a photodetector fitted with proper optics and are recorded as a function of time. Knowing the speed of light (~300 000 000 km/s) it is possible to compute the distance the photons have traveled there and back (time-of-flight principle). The interaction between the emitted laser beam (generally pulsed) and atmospheric aerosols and molecules is subject to the laws of dispersion or scattering (mainly Rayleigh, Mie and Raman) and absorption, so that this interaction manifests itself in an extinction or exponential loss of energy as the laser beam propagates through the atmosphere.

The applications of LiDAR systems are enormous, including the measurement of aerosol density, wind speed and direction, concentration of chemical compounds, temperature profiles and ceilometry studies (cloud height and thickness). In the environmental field, LiDAR systems make it possible to detect and monitor the dispersion of aerosols and other pollutants.

Over the past several years, several studies have used LiDAR systems to measure drift. From 2009 to 2021, an experimental campaign was carried out by the GRAP in which different ground spraying trials were carried out. For drift measurement, a UV (ultraviolet) LiDAR system and two types of passive collectors (nylon threads and water sensitive papers) were used simultaneously. With this work, it was concluded that LiDAR is a suitable technique for the measurement of pesticide drift since it was possible to relate the measurements obtained to those obtained by the collectors (Gregorio et al., 2016, 2014; Torrent et al. al., 2020).

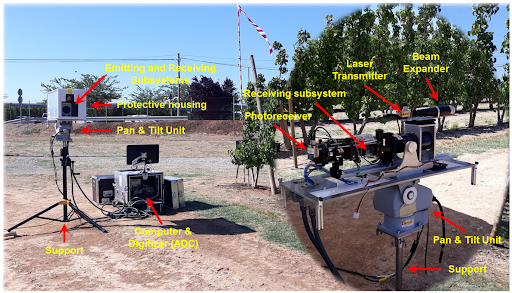

As a continuation of the previous works, the GRAP has developed a LiDAR-based system for the detection and measurement of the atmospheric drift of PPP and other types of aerosols, shown in Figure 6. The system consists of an emitter subsystem (laser) and a receiver subsystem (telescope + photodetector module) that allows the capture of a fraction of the light that returns to the detector after it has struck the target to be detected and characterized (in this case, the atmospheric drift cloud produced by an agricultural sprayer, dust, smoke, etc.). LiDAR aiming is carried out by means of an electromechanical system with two degrees of freedom: in azimuth and elevation. The result of the light captured by the photodetector module are voltage pulses which must be recorded and processed by a high performance electronic data acquisition system in order to convert it into drift measurement.

Figura 5. LiDAR-based system (left) to measure drift. Zoom of the emission and reception subsystems without the protecting case (right).

References

Abbas, I., Liu, J., Faheem, M., Noor, R.S., Shaikh, S.A., Solangi, K.A., Raza, S.M., 2020. Different sensor based intelligent spraying systems in Agriculture. Sensors Actuators A Phys. 316, 112265. https://doi.org/10.1016/j.sna.2020.112265

Campos, J., Llop, J., Gallart, M., García-Ruiz, F., Gras, A., Salcedo, R., Gil, E., 2019. Development of canopy vigour maps using UAV for site-specific management during vineyard spraying process. Precis. Agric. 20, 1136–1156. https://doi.org/10.1007/s11119-019-09643-z

Chen, L., Wallhead, M., Reding, M., Horst, L., Zhu, H., 2020. Control of Insect Pests and Diseases in an Ohio Fruit Farm with a Laser-guided Intelligent Sprayer. Horttechnology 30, 168–175. https://doi.org/10.21273/HORTTECH04497-19

del-Moral-Martínez, I., Rosell-Polo, J.R., Uribeetxebarria, A., Arnó, J., 2020. Spatially variable pesticide application in vineyards: Part I, developing a geostatistical approach. Biosyst. Eng. 195, 17–26. https://doi.org/10.1016/j.biosystemseng.2020.04.014

Escolà, A., Rosell-Polo, J.R.R., Planas, S., Gil, E., Pomar, J., Camp, F., Llorens, J., Solanelles, F., Escolà, A., Rosell-Polo, J.R.R., Planas, S., Gil, E., Pomar, J., Camp, F., Llorens, J., Solanelles, F., 2013. Variable rate sprayer. Part 1 - Orchard prototype: Design, implementation and validation. Comput. Electron. Agric. 95, 122–135. https://doi.org/10.1016/j.compag.2013.02.004

Gil, E., Escolà, A., Rosell, J.R., Planas, S., Val, L., 2007. Variable rate application of plant protection products in vineyard using ultrasonic sensors. Crop Prot. 26, 1287–1297. https://doi.org/10.1016/j.cropro.2006.11.003

Gregorio, E., Rosell-Polo, J.R., Sanz, R., Rocadenbosch, F., Solanelles, F., Garcerá, C., Chueca, P., Arnó, J., del Moral, I., Masip, J., Camp, F., Viana, R., Escolà, A., Gràcia, F., Planas, S., Moltó, E., 2014. LIDAR as an alternative to passive collectors to measure pesticide spray drift. Atmos. Environ. 82, 83–93. https://doi.org/10.1016/j.atmosenv.2013.09.028

Gregorio, E., Torrent, X., de Martí, S.P., Solanelles, F., Sanz, R., Rocadenbosch, F., Masip, J., Ribes-Dasi, M., Rosell-Polo, J.R., 2016. Measurement of spray drift with a specifically designed lidar system. Sensors (Switzerland) 16, 1–15. https://doi.org/10.3390/s16040499

Llorens, J., Gil, E., Llop, J., Escolà, A., 2010. Variable rate dosing in precision viticulture: Use of electronic devices to improve application efficiency. Crop Prot. 29. https://doi.org/10.1016/j.cropro.2009.12.022

Román, C., Arnó, J., Planas, S., 2021. Map-based zonal dosage strategy to control yellow spider mite (Eotetranychus carpini) and leafhoppers (Empoasca vitis & Jacobiasca lybica) in vineyards. Crop Prot. 147, 105690. https://doi.org/10.1016/j.cropro.2021.105690

Román, C., Llorens, J., Uribeetxebarria, A., Sanz, R., Planas, S., Arnó, J., 2020. Spatially variable pesticide application in vineyards: Part II, field comparison of uniform and map-based variable dose treatments. Biosyst. Eng. 195, 42–53. https://doi.org/10.1016/j.biosystemseng.2020.04.013

Román, C., Peris, M., Esteve, J., Tejerina, M., Cambray, J., Vilardell, P., Planas, S., 2022. Pesticide dose adjustment in fruit and grapevine orchards by DOSA3D: Fundamentals of the system and on-farm validation. Sci. Total Environ. 808, 152158. https://doi.org/10.1016/j.scitotenv.2021.152158

Salcedo, R., Zhu, H., Zhang, Z., Wei, Z., Chen, L., Ozkan, E., Falchieri, D., 2020. Foliar deposition and coverage on young apple trees with PWM-controlled spray systems. Comput. Electron. Agric. 178, 105794. https://doi.org/10.1016/j.compag.2020.105794

Torrent, X., Gregorio, E., Rosell-Polo, J.R., Arnó, J., Peris, M., van de Zande, J.C., Planas, S., 2020. Determination of spray drift and buffer zones in 3D crops using the ISO standard and new LiDAR methodologies. Sci. Total Environ. 714, 136666. https://doi.org/10.1016/j.scitotenv.2020.136666

Wandkar, S.V., Bhatt, Y.C., Jain, H.K., Nalawade, S.M., Pawar, S.G., 2018. Real-Time Variable Rate Spraying in Orchards and Vineyards: A Review. J. Inst. Eng. Ser. A 99, 385–390. https://doi.org/10.1007/s40030-018-0289-4